What Are Bagpipes Made Of?

Dec 12, 2024

The Great Highland Bagpipes are the iconic bagpipes that are famous around the world as a symbol of Scottish culture, with their distinctive, piercing sound.

But what are they made of?

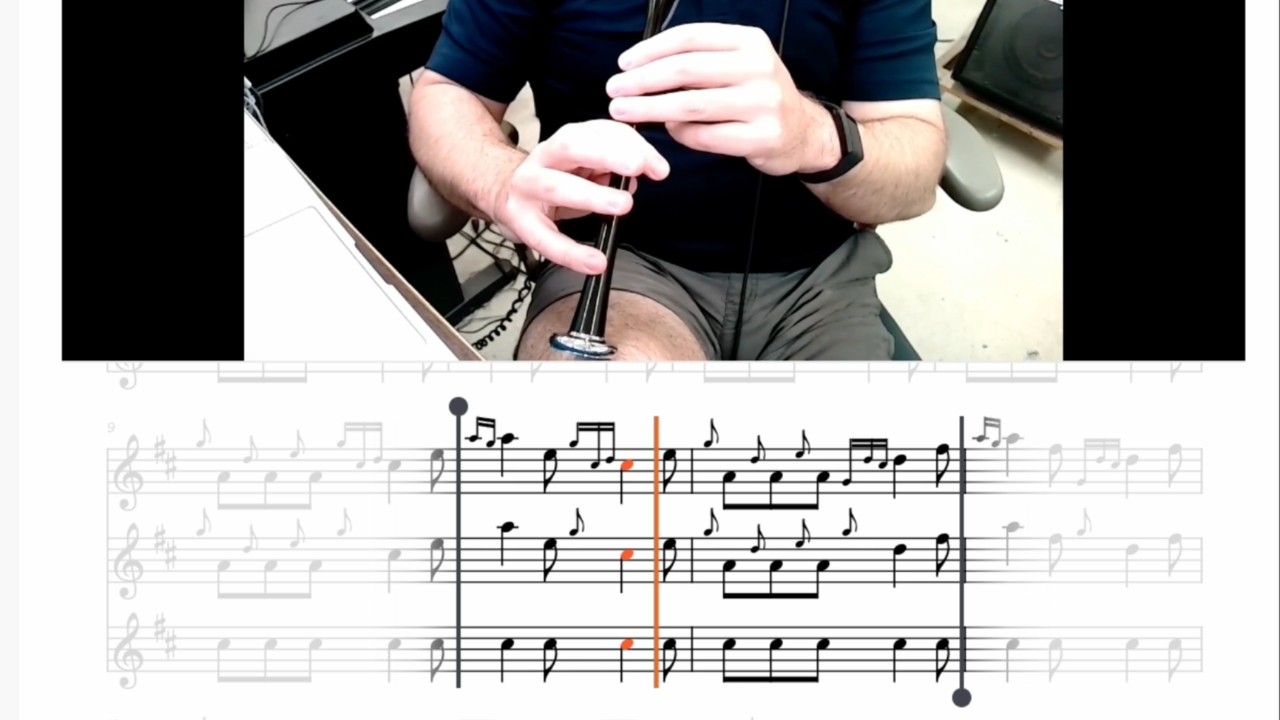

The actual 'pipes' of the instrument – that is, the drones, blowpipe and chanter – can be made of a range of materials.

Good quality bagpipes from reputable makers are most commonly made of African blackwood (dalbergia melanoxylon). But that hasn't always been the case – and even today, bagpipes have been, and still are, made of a variety of materials.

The Earliest Bagpipes Were "Bog"pipes

Much of the early history of Scottish bagpipe material is lost to history. But we can make some educated guesses. It’s safe to assume that in the 17th and 18th centuries African wood, or any tropical hard wood for that matter, would not be found in Scotland.

One of the oldest known sets of highland bagpipes, a two-drone version similar to the Spanish gaita, is made of Bog Oak, a type of bog wood.

Bog wood is a very interesting material. It is actually a type of pre-fossil – wood that has been buried in peat bogs and preserved by the anaerobic nature of the bog. In the past, over time, the bogs expanded and contracted, allowing dead trees to become buried in the bog. Some of these trees have been buried for hundreds or even thousands of years.

Peat bogs are found in very few areas in the world. They form in areas that are cool and wet. They usually have poor drainage and are in oceanic climates. The northern Highlands in Scotland are dominated by the bogs and peat bogs make up almost 23% of the land area in Scotland.

Bog wood found in Scotland is generally oak, pine, and yew. The wood takes on its dark brown or black appearance due to the tannins found in the bogs. It is incredibly hard and for the most part holds its original shape, which made it popular for furniture, decorations, wood block printing – and of course, for instruments like the bagpipes.

Early Timbers: European and British Hardwoods

During the Renaissance most woodwind instruments were made of European boxwood (buxus sempervirens). Boxwood is found from southern England to northern Morocco and across the Mediterranean. It's a very slow growing tree that has little to no grain, and is the hardest wood native to Europe. This made it ideal for woodwind instruments, including the precursors to oboes, clarinets, and early recorders.

Since boxwood was found in the south of England, and because it was a commonly used in other instruments, it seems likely that it could have been used in bagpipes. The problem is that there are no bagpipes that have been found that go further back than the 18th century.

A New Timber Enters The Game: Blackwood

It wasn’t until Great Britain became involved in Atlantic triangular trade in the 18th century that tropical hardwoods started to make their way to Scotland. Ships returning from the colonies would bring these hardwoods back to be used in furniture, decorations, and musical instruments.

The Great Highland Bagpipe did not take on the form we know today—two tenor drones, one bass in the size and length we know—until the 1780s. In fact, we believe that the instruments we know today were originally produced as “prize pipes” awarded during piobaireachd competitions. Even then, they were made of a variety of woods, both local and from the colonies. It wasn’t until the very early 1900s that African blackwood became the default material for bagpipes.

African blackwood, part of the rosewood family, is found in the dry regions of Africa, Senegal to Eritrea down to the northern and eastern parts of South Africa. The tree itself usually grows to about 15 meters. The dry climate causes the wood to grow very slowly – only mature trees of around 20-30 years old are suitable for musical instruments. This slow growth is what makes the wood so dense. The older the tree, the better quality of the heartwood, the dark center core of the tree, which is what we call "blackwood." In the early days of British colonial expansion, it was not unusual for bagpipes to be made from trees that were more than 100 years old.

The dense hardness of the wood makes it ideal for musical instruments. When properly cured, the wood can be easily machined, as it's dimensionally stable and naturally moisture resistant. These qualities make it ideal to be turned and hollowed out for musical instruments.

Popularity Turns to Endangerment

In the early period of transatlantic trade, blackwood was almost regarded as scrap wood. There are accounts of trade ships using it as ballast and then discarding once it arrived in Great Britain.

African blackwood was a very common tree up until the mid 20th century. It has been becoming very popular, along with other hardwoods in the rosewood family, in furniture and decorative carvings especially in Asia. But due to its overuse and slow growth, many members of the rosewood family are now commercially extinct in their natural regions and have been added to the CITES list of protected species. African blackwood was added to this list in 2017, as part of a broader listing for the entire Dalbergia genus, which doesn't ban trade but regulates it to ensure sustainability. Efforts are ongoing to balance demand for African blackwood with conservation measures to ensure its long-term availability.

The Dawn of Plastic Pipes

In the 1950s, bagpipe makers started experimenting with plastics in bagpipes. Acetyl Delrin and Polypenco have become more common over time, and many pipe bands now play with chanters made from this synthetic material.

Most of the major bagpipe makers now produce full sets of bagpipes made entirely of polypenco. Today's makers are also experimenting with exotic hardwoods such as cocobolo and mopane, which share similar qualities as blackwood. Natural woods though, face the same risk of over harvesting and thus could face the same commercial restrictions in future as other hardwoods such as ebony, rosewood, and blackwood.

Where To From Here?

Reputable makers are still predominantly using African blackwood, and it continues to be the preferred choice among pipers.

But conservation efforts, a dwindling supply of quality hardwoods, and ongoing innovation will likely shape the future of bagpipe materials. Plastic varieties continue to be popular, and several innovative makers have begun exploring how 3D printing technology could help produce cheaper and open source sets as well.

It's going to be fun to see what new and exciting developments there are in future.

Stay connected - subscribe to our free Weekly Digest!

Get bagpipe knowledge delivered to you every Monday! Tips and tricks, podcasts, special offers, and more.

We hate SPAM. We will never sell your information, for any reason.